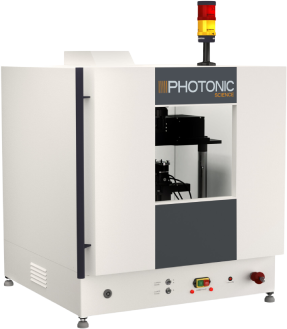

2D MICRO RADIOGRAPHY

High-Resolution Customizable X-Ray Imaging Solution

Cutting-edge, adaptable 2D Micro Radiography System, equipped with Photonic Science’s industry-leading sCMOS based X-ray cameras that deliver exceptional microscopic-level resolution.

We excel in creating bespoke solutions tailored to your specific requirements. Our systems are designed for versatile applications, including medical research and development, non-destructive testing (NDT), archaeology, material science, electronics, and forensic analysis

Features & Benefits

Complete System

Fully integrated, with table, for plug-n-play operation

Sample Observation Camera

Postion and monitor the sample while in the chamber

Motorized Sample Mount

Automated sample scanning and positioning

Sample Observation Camera

High sensitivity, short exposures and low noise imaging

X-Ray Imaging

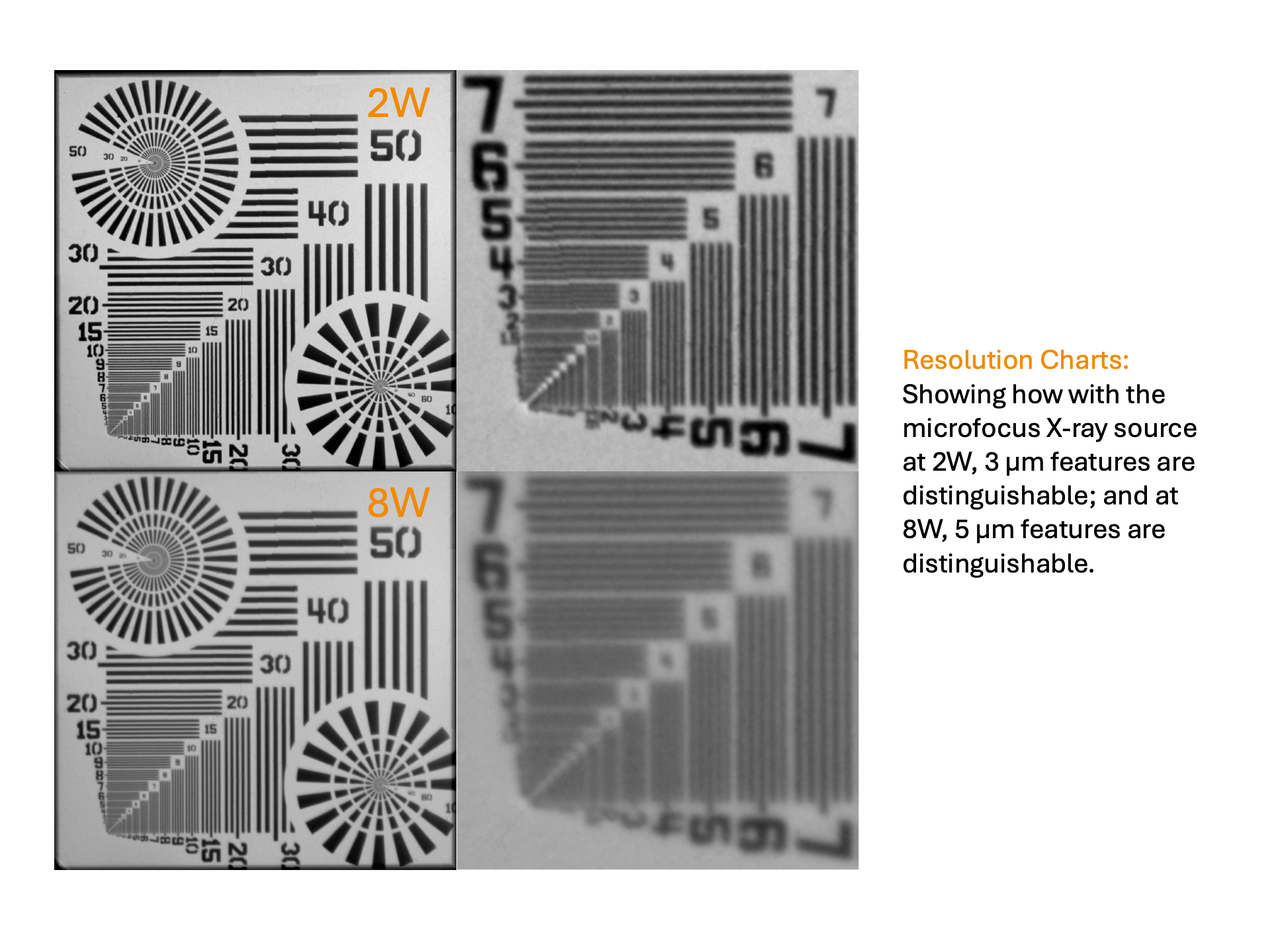

High resolution, down to 3 µm

Targeted Magnification

1x to 10x variable magnification for flexible resolution

On-site/Remote Install and Training

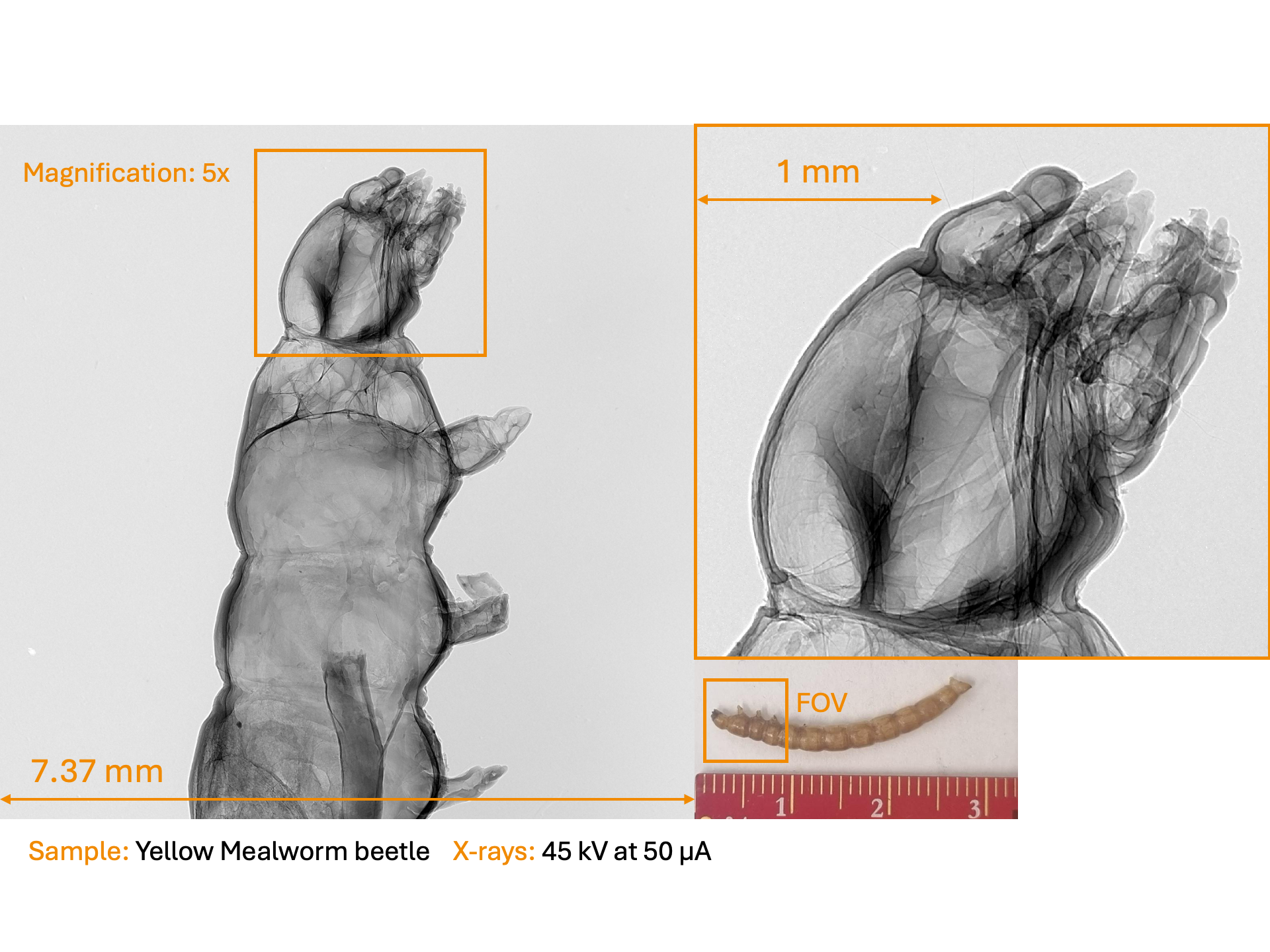

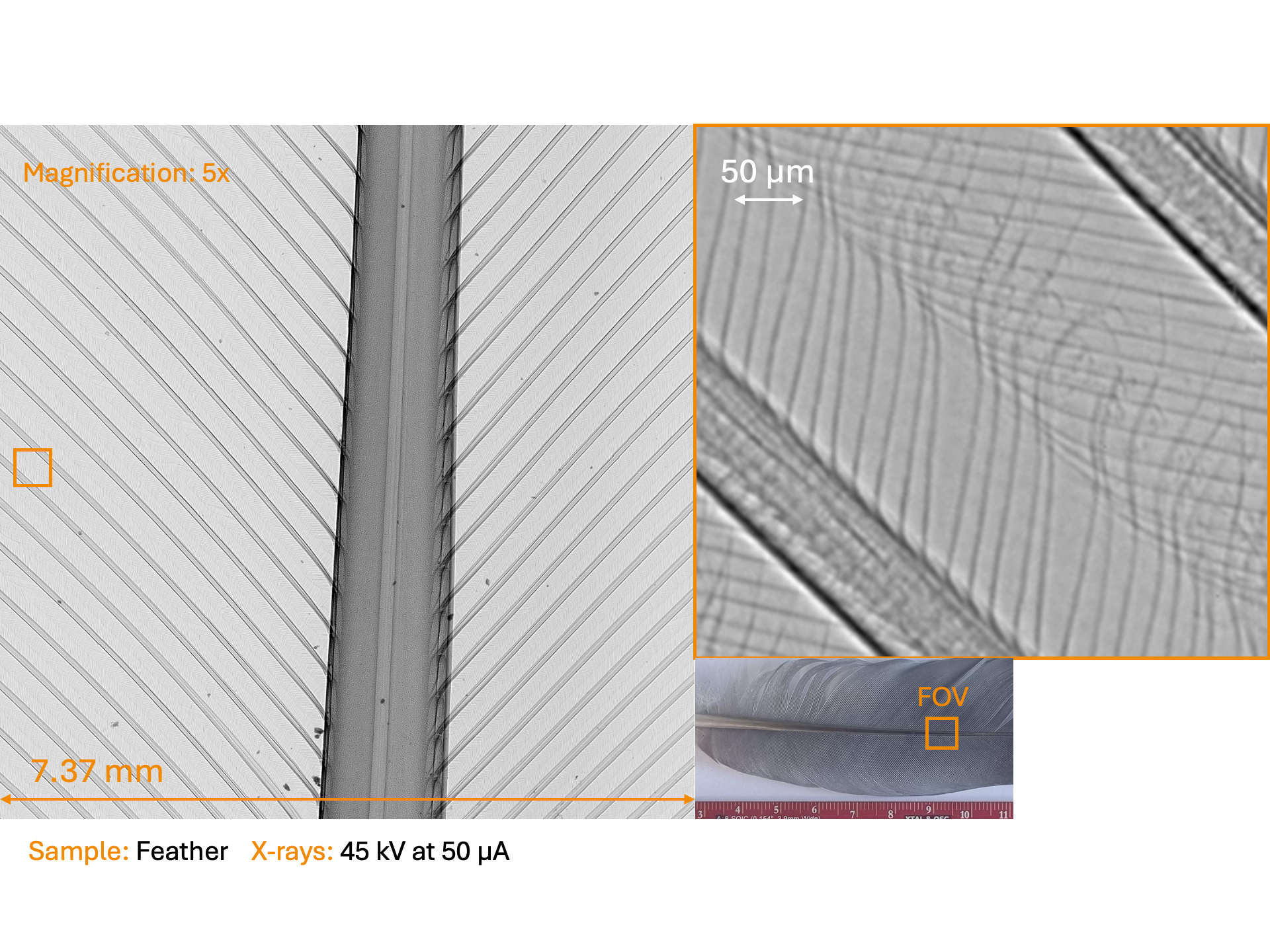

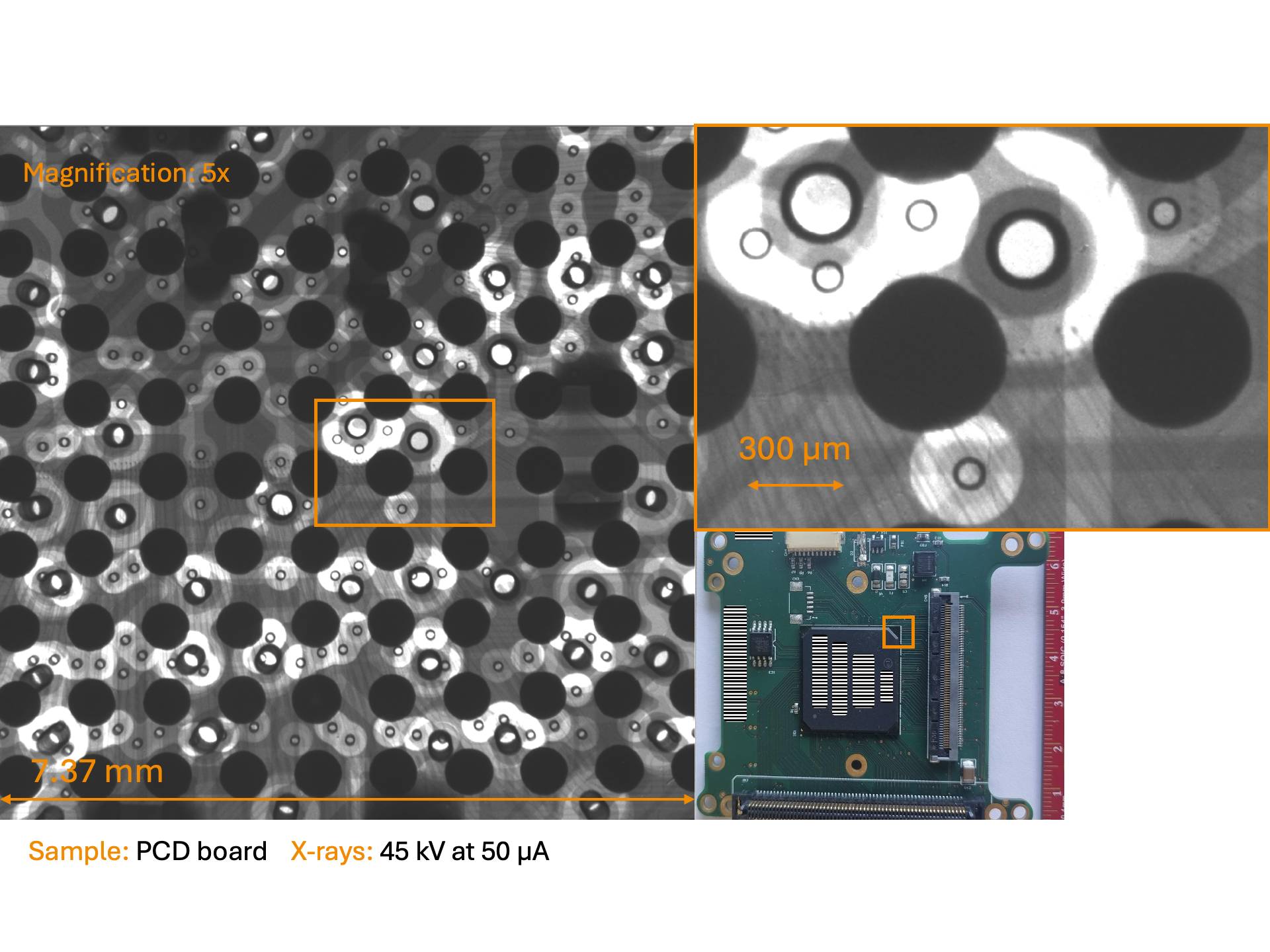

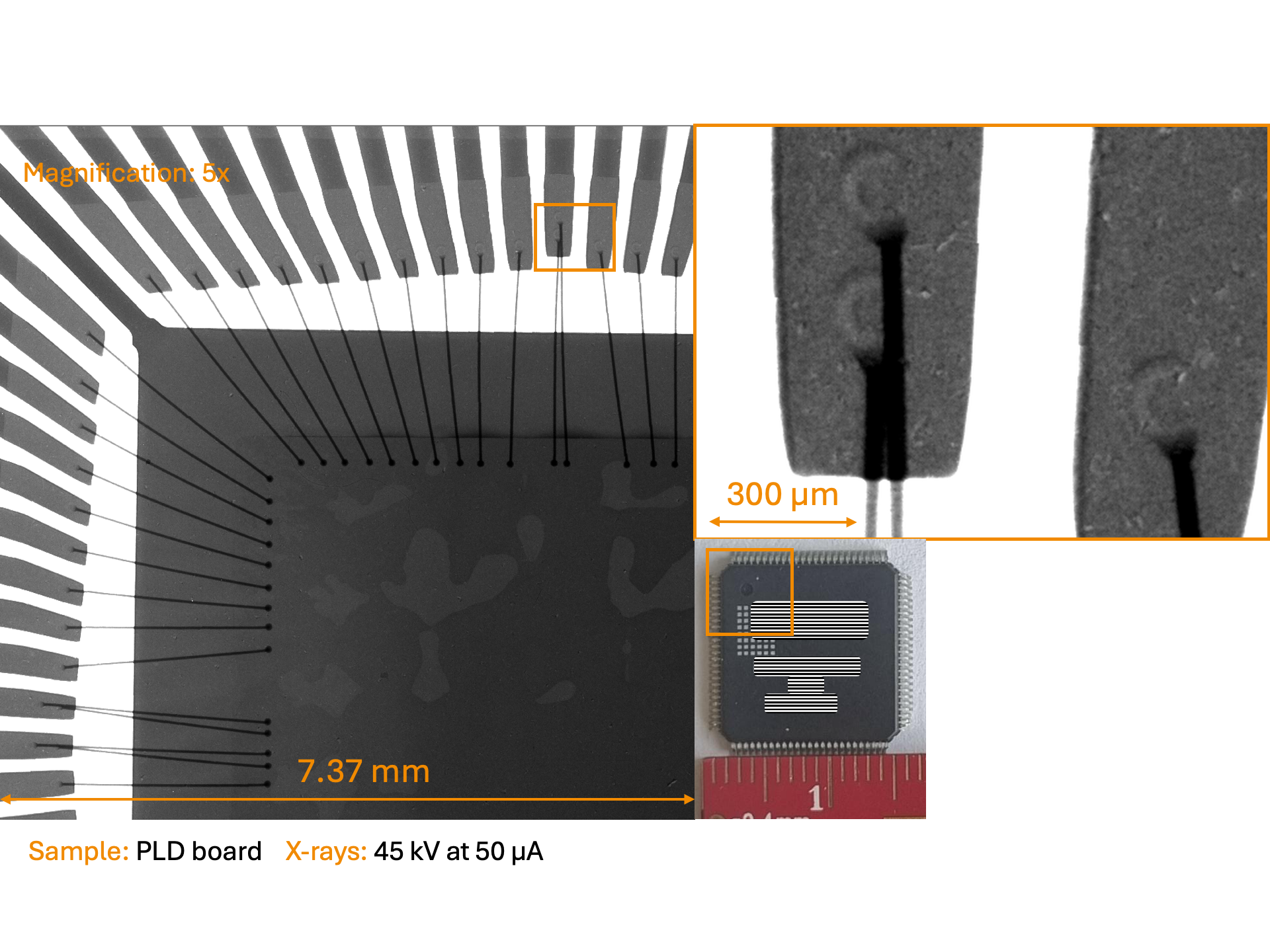

2D MICRO RADIOGRAPHY SAMPLE IMAGES

2D MICRO RADIOGRAPHY SYSTEM OPTIONS

| 2D RADIOGRAPHY | RAPID IMAGING | HIGH RESOLUTION |

|---|---|---|

| Resolution at the Target | 3 μm at 2.5 W with 5x magnification - 5 μm at 8W with 5x magnification | ~ 30 μm |

| Magnification Range | 5x to 10x | up to |

| Area of Illuminated Target | 7.34mm2 (5x mag) or 3.67mm2 (10x mag) with maximum sample size of 20 mm by 30mm, larger sizes available on request. | ~36.7mm2 or 65.5 mm2 |

| Typical Exposure Time (sample dependent) | ~2s | >1s |